Aug 2011

Effect of Fasteners and Defects in the Protected Zone on the Performance of Moment Frames

This research is investigating the effect of fasteners and defects applied in the protected zone on the ductility, low cycle fatigue performance, and inelastic rotation capacity of steel beam-to-column moment frame connections.

Special moment resisting frames (SMRF) depend on large inelastic strains in the beam-to-column connections to dissipate seismic energy and protect buildings from collapse. The ANSI / AISC 341 Seismic Provisions for Structural Steel Buildings define the ends of the beams in a SMRF as protected zones at the locations where large inelastic strains are expected, and there are strict limitations about the types of defects or fasteners allowed in this region.

The restriction on fasteners in the protected zone creates issues in construction due to the difficulty in communicating these restrictions to all subcontractors and future users of the building. Common unapproved attachments that have been identified are the attachment of steel deck to the beam top flange, attachment of cold-formed steel wall track to the underside of the beam, attachments for mechanical / electrical systems, and others.

A series of research projects have been conducted to identify the types of defects and fasteners that will cause the connection to have insufficient ductility for use in high seismic zones. Types of defects and fasteners investigated include power actuated fasteners, arc spot welds, grinding repairs per AWS D1.8, welding repairs per AWS D1.8, and sharp notches.

A two part testing program was conducted that uses a limited number of test specimens to represent a wide range of connection types and configuration parameters. The first phase of the research involves full-scale beam-to-column connection tests. The second phase of the research used smaller coupon specimens to represent the flange undergoing local buckling.

Test Setup at the Thomas M. Murray Structural Engineering Laboratory

Test Setup at the Thomas M. Murray Structural Engineering Laboratory

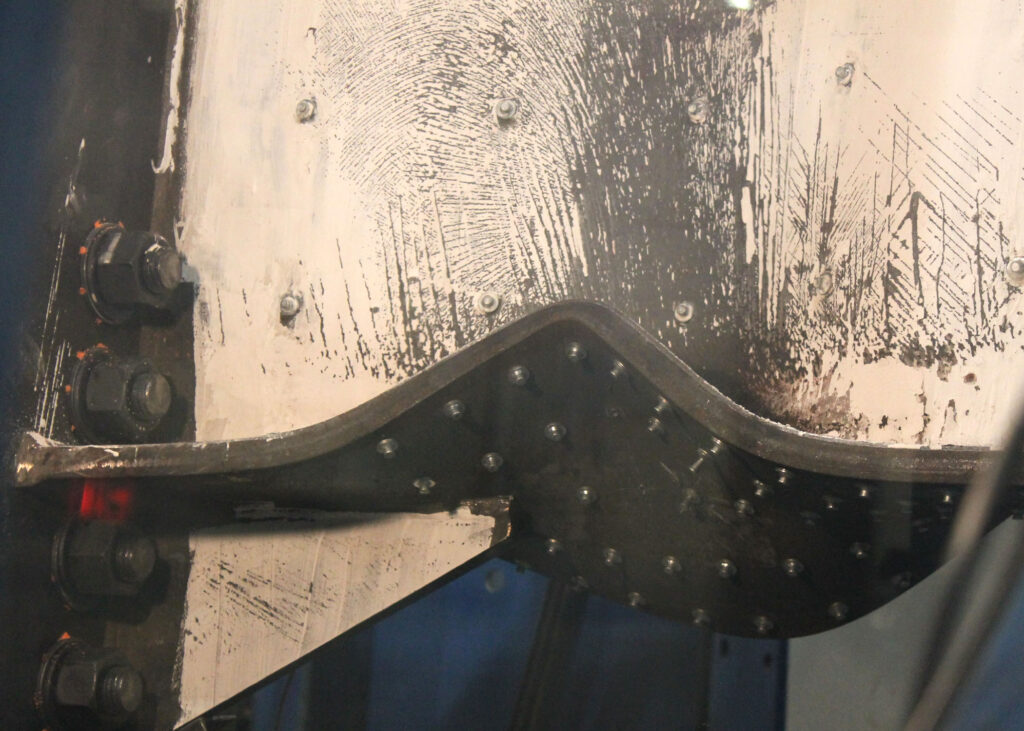

Full-Scale Beam-to-Column Moment Connection with Powder Actuated Fasteners Applied to the Flange Demonstrating Significant Ductility and Deformation Capacity

Full-Scale Beam-to-Column Moment Connection with Powder Actuated Fasteners Applied to the Flange Demonstrating Significant Ductility and Deformation Capacity

Picture of a specimen with a grid of power actuated fasteners that demonstrated similar behavior as a specimen without any fasteners or defects. See Toellner et al. (2015) for details.

Picture of a specimen with a grid of power actuated fasteners that demonstrated similar behavior as a specimen without any fasteners or defects. See Toellner et al. (2015) for details.

Want to see a video? Click here! The video is best viewed full screen with HD quality setting.

Stevens, R.T., Hebdon, M.H., and Eatherton, M.R.(2021) Evaluating the Fracture Potential of Steel Moment Connections With Defects and Repairs, Virginia Tech Structural Engineering and Materials Report No. CE/VPI-ST-21/02.

Toellner, B.W., Watkins, C.E., Abbas, E., and Eatherton, M.R. (2015) “Effect of Powder Actuated Fasteners on the Seismic Performance of Steel Moment Frame Connections” Journal of Constructional Steel Research, Vol. 105, pp. 174-185

Abbas, E., and Eatherton, M.R. (2014) A Low Cycle Fatigue Testing Framework for Evaluating the Effect of Artifacts on the Seismic Behavior of Moment Frames, Virginia Tech Structural Engineering and Materials Report No. CE/VPI-ST-14/06

Eatherton, M.R., Toellner, B.W., Watkins, C.E., and Abbas, E. (2013) The Effect of Powder Actuated Fasteners on the Seismic Performance of Protected Zones in Steel Moment Frames, Virginia Tech, SEM Report Series, Report No. CE/VPI-ST-13/05

More Research:

- Buckling Restrained Brace Subassemblage Testing

- Testing of Steel Crates

- Development of a Spectral Matching Algorithm

- End-Plate Moment Connections

- Self-Centering Beams for Resilient Earthquake Resistance

- Ring-Shaped Steel Plate Shear Walls

- Super High Tension Bolts

- Controlled Rocking of Steel Braced Frames with Replaceable Energy Dissipating Fuses

- Development of a Self-Centering Buckling Restrained Brace

- Understanding Structural Response During Earthquakes Using Wavelet Transforms

- Characterizing Hysteretic Behavior of Cold-Formed Steel Members and Connections